Finding the best compromise between price and quality

25% of pharmaceutical companies' expenses concern logistics

Never breaking the cold chain is the foremost constraint when transporting thermal sensitive drugs. This involves keeping the product at a constant temperature throughout the transport, including during storage periods and during transfer to different modes of transport.

The choice of the insulated packaging solution is decisive! There are numerous solutions for cold chain transport. It is therefore essential to understand the techno-economic issues related to the choice of performance and to the use of thermal packaging system.

The expense of supporting the pharmaceutical supply chain represents 25% of the costs borne by the pharmaceutical companies. The expenses of supporting the logistics of the cold chain for drugs are the weightiest of these expenses. Optimising the process – making it safer and more efficient – could be a source of significant savings.

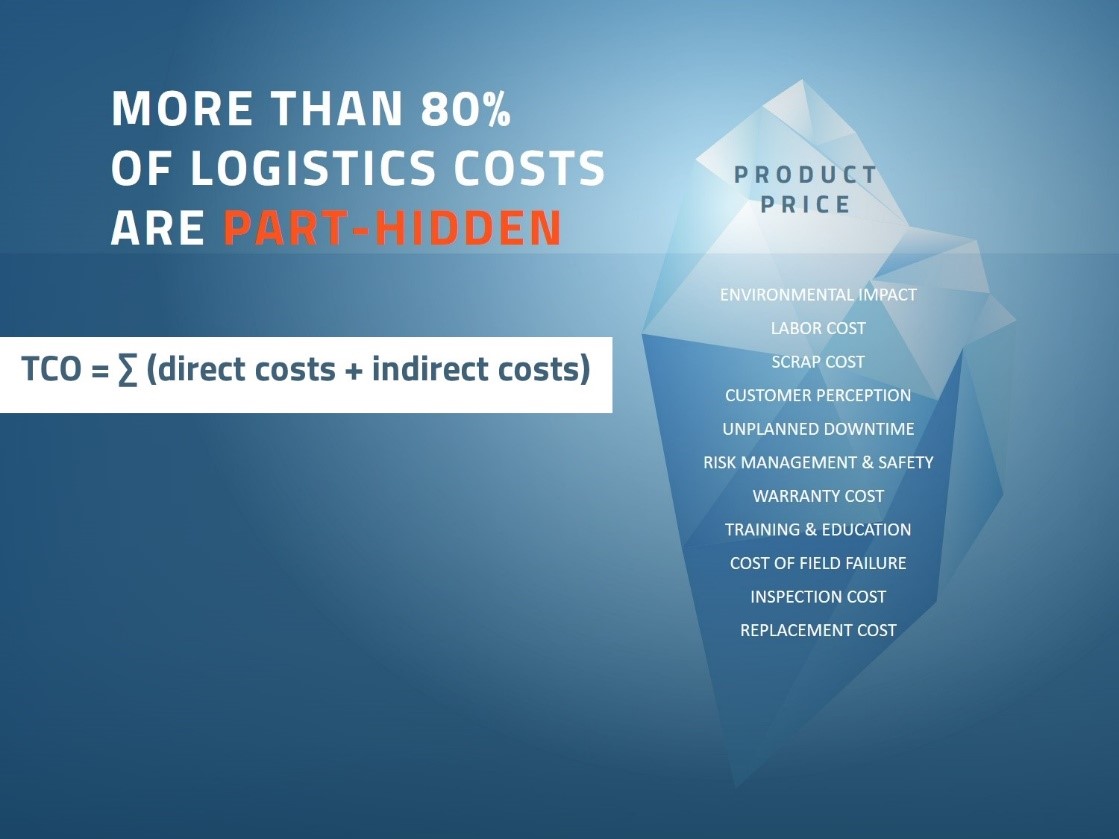

More than 80% of the costs of pharmaceutical logistics costs are hidden costs

The TCO (Total Cost of Ownership) determines the direct and indirect costs of owning and using a cold chain packaging solution. It makes it possible to evaluate the overall financial impact of a purchase decision in order to move towards the best choice of cold chain packaging solution.

While the purchase price is an important and easily identifiable criterion, analysis of the life cycle of insulated packaging reveals that other ancillary costs can have a significant impact on the overall cost of the packaging solution: costs such as those involved in loading time, mode of transport, weight, etc.

While the purchase price is an important and easily identifiable criterion, analysis of the life cycle of insulated packaging reveals that other ancillary costs can have a significant impact on the overall cost of the packaging solution: costs such as those involved in loading time, mode of transport, weight, etc.

In fact, the purchase price represents only part of the overall cost of implementing the insulated shipping solution: it is the tip of the iceberg.

The costs of transport, storage, preparation, packaging, retrieval of packaging if is reusable, and the service provider’s after-sales service are among the costs to consider, not to mention the costs related to security risks (loss, theft, temperature deviations ... ).

That is the point of a TCO analysis of reusable insulated shipping packaging: finding the best compromise between price and quality.

Would you like to consult about choosing an insulated shipping solution for streamlining your temperature-controlled pharmaceutical transportation?