250,000

shipping units produced annually

4 separate companies

within the Sofrigam Group

18,000 m2

used solely for the manufacture of packaging

40 years

of innovation and performance

History

Our Mission

Help you to heal the world

Our aim is to help you to improve the efficacy of medicine by facilitating the movement of your innovations more easily around the world.

Our mission has two objectives :

- to maintain your products at perfectly stable temperatures throughout their shipment;

- to help you improve your logistics chain.

We offer our our expertise, acquired over 40 years’ of experience, alongside the most important contacts in the health field to help you reduce your logistic costs and to minimise your environmental footprint – while simultaneously meeting the regulatory requirements in the cold chain transport of pharmaceutical products.

Environmental policy

Quality policy

Your level of standards is ours

Every day we work with our collaborators, partners and suppliers to ensure maximum customer satisfaction in terms of quality control and time scales, constantly seeking improvements in our methods.

Sofrigam will help you protect the integrity of your high value-added products without the need to compromise.

All our solutions meet the European directives in Good Distribution Practice guidelines (GDP), the object being to guarantee the quality and integrity of the health products at all levels in the distribution circuit. This requires an on-going, rigorous reviewing process in terms of our partners and suppliers to confirm that they maintain our values and standards of quality.

OUR CERTIFICATIONS DEMONSTRATE OUR TRUE COMMITMENT

Our Quality Management is certified ISO 9001 and reflects two main commitments: client satisfaction and continual improvement. We are establishing a system to constantly seek to improve the manufacturing process of our packaging as well as monitoring client satisfaction. Our Quality Management system is regularly audited by the organisation that issues the ISO certificates and is followed closely by our pharmaceutical clients.

Additionally, our Environmental Management is certified ISO 14001. To validate our guarantee of regular improvement in environmental performance as well as controlling our energy expenses, we confirm that at all times we follow a policy of continuous improvement to reduce our environmental footprint in the short, medium and long term, as well as limiting our energy expenses.

>>> Consult our Quality and Environmental Policy

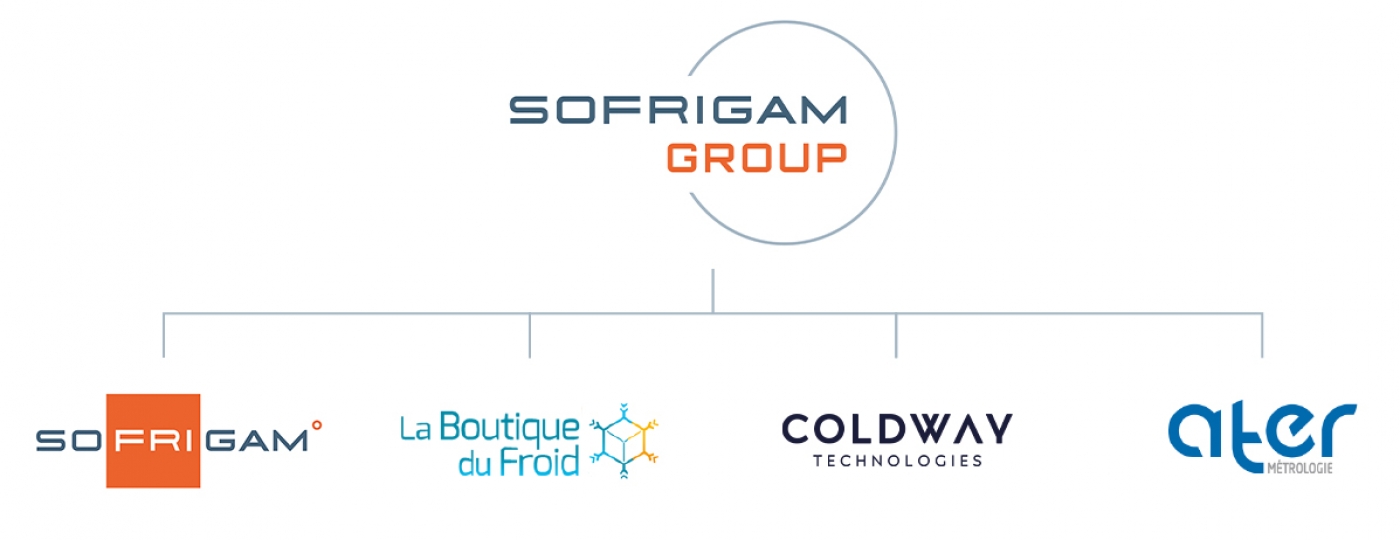

Sofrigam Group

THE STRENGTH OF AN INTERNATIONAL GROUP

Sofrigam is now an international group, comprising of companies meeting the needs of the cold chain management throughout the whole pharmaceutical supply chain, from the production of medication to last-mile logistics.

Sofrigam designs and develops cold chain management solutions (containers, packaging, bags and pouches) for pharmaceutical, biotechnological and chemical companies.

Initially specialising in passive packaging, today Sofrigam has turned towards active, innovative technologies with Coldway Technologies. The synergy between the technical nature of the Sofrigam and the Coldway Inside° technology – a production system of autonomous thermic energy – represents a major innovation in the field of cold production and storage.

Those who are involved with the last-mile logistics – in either the health field or the food industry – will be interested in La Boutique du Froid (The Cold Shop), an on-line platform with experts available to assist you to seek cold chain management solutions. All the recommended pathways suggested by members of the Sofrigam Group are tested, pre-qualified and validated by the thermal testing laboratory Ater Métrologie, to ensure their reliability and performance according to the norms and regulations in force.

Recruitment

Sofrigam is regularly looking for new talent. Do you want to bring new perspectives to your career? Would you like to participate in the development of a dynamic and innovative company with an international reputation? Join our teams!