ISO 9001, external audits: a well-established quality control process

We manufacture temperature-controlled packaging solutions for the biggest names in the pharmaceutical industry. These big names regularly audit our production site, which is another reason for us to pay special attention to the quality of our packaging solutions.

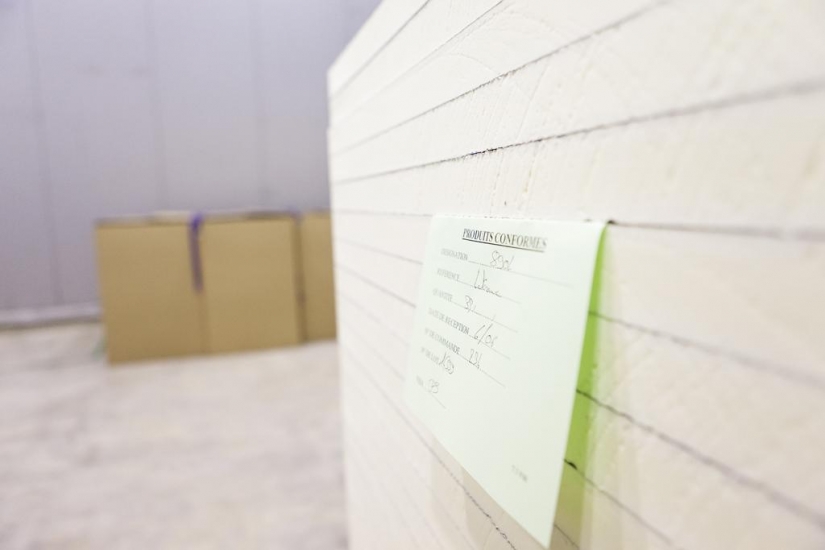

In fact, Sofrigam has implemented a quality control process alongside its packaging solution manufacturing process to respond to the requirements of ISO 9001 certification. Organizational methods, management of non-conformities, followed by client satisfaction are some of the criteria taken into account by the ISO 9001 certification which standardizes the quality management system.

A wavelength meter to measure the thermal quality of the components of insulated packaging solutions

Sofrigam is working in strict collaboration with the thermal testing laboratory Ater Métrologie to test, qualify and validate its insulated packaging solutions. Recently, the laboratory has acquired a wavelength meter, a device for measuring the thermal resistance of an insulating material.

Although Sofrigam has a strong Quality team which systematically checks the raw materials upon arrival and the end-products (insulated boxes and packaging solutions, etc.), Sofrigam is going even further in its quality control process with the wavelength meter. This device, also known as a thermal flowmeter, measures the thermal resistance of an insulating material. Thibault Pech, a R&D engineer within the Ater Métrologie laboratory, explains how it works:

“The wavelength meter consists of two plates which sandwich the insulating material. Each plate is set at a different temperature, of between -10°C and +90°C inclusive. If you want to know the thermal conductivity of a material at +5°C for example, you set one plate at +10°C and the other at 0°C. Once the balance is reached, the thermal flowmeter will measure the thermal flow exchanged between both plates and calculate the thermal resistance of the material.”

Thermal flowmeter

It represents a tremendous tool for Sofrigam which uses it to control the quality of the components of its packaging solutions. In fact, the wavelength meter allows Sofrigam to not only verify the thermal properties of the polyurethane insulating material, the external cardboard of its insulated boxes or even the fabric coverings used in its insulated pouches, but also verify the evolution of the thermal conductivity of these materials over time. And this allows us to offer our clients even more efficient insulated packaging solutions!